Project Description

POPEFLEX – VENTING & NON VENTING TUBE

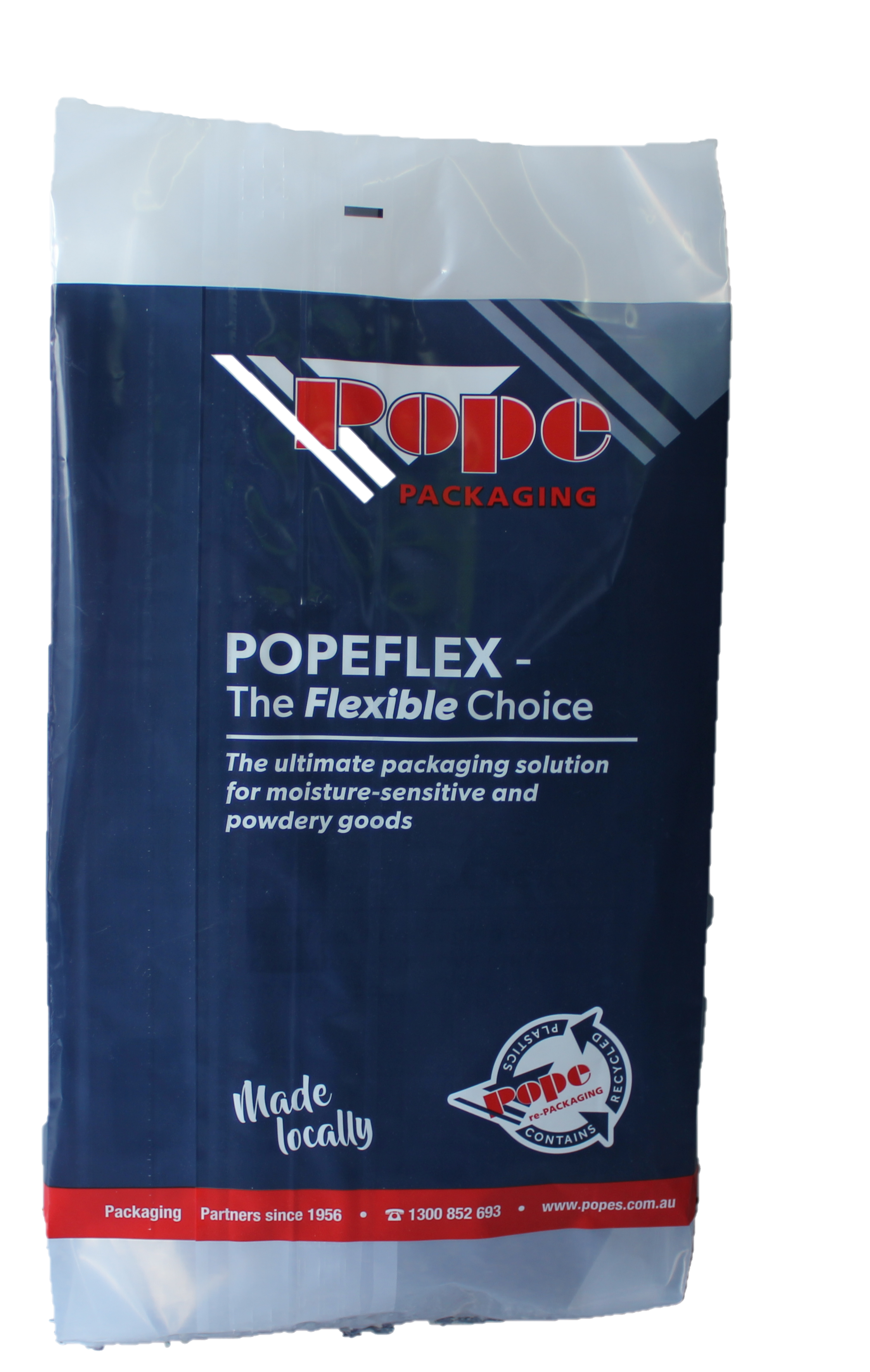

POPEFLEX is the ultimate solution for moisture-sensitive and powdery goods.

Click here to download the Popeflex Brochure

We make POPEFLEX on our newly acquired Windmoller & Holscher Polytex universal tuber, the first installed in Australia. This class-leading tuber converts flat polyethylene (PE) film into a form-fill-seal (FFS) ready tube. It has the versatility to deliver customisable solutions and significant cost savings for our clients.

It can be supplied in a variety of forms – including preformed bags, self-venting & non-venting tubular rolls – and configured in a variety of ways to suit most situations.

The POPEFLEX range of tailor-made solutions is the result of combining the latest PE tubing technology with our vast packaging experience, enabling us to deliver solutions that meet our customer’s requirements.

POPEFLEX advantages include:

- Superior moisture barrier

POPEFLEX’s moisture barrier is more effective than paper packaging allowing goods such as dry mixes (mortar, plaster and cement) and other hygroscopic products to be stored outdoors for extended periods and at any time of the year.

- Optimum fill-rate performance

POPEFLEX optimises filling speeds, due to superior deaeration rates, when tailored for your specific filling equipment and batch requirements.

- Superior print quality

Excellent packaging design is a potent marketing tool and can create a lasting competitive advantage. POPEFLEX packaging features 8C Flexo printing, resulting in stunning hi-res images that attract attention, contribute to instant brand recognition and create a favourable overall impression with consumers.

- Unmatched impact and tear resistance

POPEFLEX bags are less prone to damage and leaks during transportation and storage due to their superior strength, impact and tear resistance.

- Cleanliness and safety

With its unique variable ventilation system, POPEFLEX maintains a clean and dust-free working environment even when bagging extra-fine powdery materials.

- Environmental sustainability

POPEFLEX is 100% recyclable.

- Full Customisation

POPEFLEX is highly adaptable and has a wide range of customisable options. Our product specialists have vast technical experience in polymer technologies enabling them to tailor solutions that deliver the performance, efficiencies and product characteristics required.